-

- 4×2 Dump Truck

- Engine power: 290 HP

- GVW: 19,000 kg

- Cargo box volume: 8-10 m³

- Rear axle type: 13-ton dual reduction drive axle

- This 4×2 dump truck is equipped with a 290 HP engine, 9-speed transmission, and a 13-ton dual reduction rear axle. Designed for efficient short-haul and urban transport tasks, it offers a balance of power and payload for smaller-scale construction and municipal operations. View details

-

- 6×4 Dump Truck

- Engine power: 380-420 HP

- GVW: 26,000 kg

- Cargo bed volume: 12–20 m³

- Rear axle type: 13-ton dual-stage reduction drive axle

- The 6×4 dump truck features a powerful drivetrain built for demanding off-road and construction tasks. Powered by either the Weichai WP10 or WP12 engine, this construction truck delivers a maximum output of 420 HP at 2100 rpm, combined with a 12-speed transmission and dual-stage reduction rear axle View details

-

- 8×4 Dump Truck

- Engine power: 380 HP

- GVW: 31,000 kg

- Cargo box volume: 20–25 m³

- Rear axle type: 13-ton dual reduction drive axle

- This 8×4 dump truck is equipped with a powertrain featuring a 420 HP engine, a 12-speed manual transmission, and dual reduction rear axles. It can be configured with Weichai WP10, WP12, or WP13 engines, meeting Euro 2 and Euro 3 emission standards. View details

Technical Features

Expand All

Our tractor units are available in two cab series: NG80 and V3, allowing users to choose different configurations based on operational requirements.

Complete cab system developed using Daimler-Benz technology

Complete cab system developed using Daimler-Benz technology

- Developed using the complete cab technology introduced from Daimler-Benz.

- The NG80 cab features a semi-floating suspension system with high structural rigidity and energy absorption, providing enhanced driver protection.

- Manufactured with high-strength steel panels through integrated stamping, combined with a multi-cavity structural design for increased rigidity.

- Successfully passes pendulum impact testing and complies with EU crash safety certification standards. Ideal for engineering applications and mixed operating conditions

V3 cab engineered in collaboration with EDAG Germany and benchmarked to Daimler-Benz standards

V3 cab engineered in collaboration with EDAG Germany and benchmarked to Daimler-Benz standards

- Developed in collaboration with EDAG Germany and benchmarked against Daimler-Benz standards, the V3 cab is a wide-body design created through a forward engineering process.

- The V3 cab features a four-point floating suspension system, offering high structural strength and energy absorption while enhancing overall driving comfort.

- Built with high-quality steel panels through full-body integrated stamping, along with a multi-cavity structure that increases cab rigidity.

- Successfully passes pendulum impact tests and complies with EU crash safety certification standards. Optimized for long-distance highway transport applications.

Daimler-Benz frame technology with proven load-bearing performance

Daimler-Benz frame technology with proven load-bearing performance

Developed using Daimler-Benz technology, the frame features a variable-section, fish-belly-shaped composite beam design. The inner and outer frame rails are formed through a single-pass stamping process, delivering outstanding load-bearing performance. The result is a frame system renowned for its exceptional durability and structural strength, widely trusted in demanding heavy-load applications.

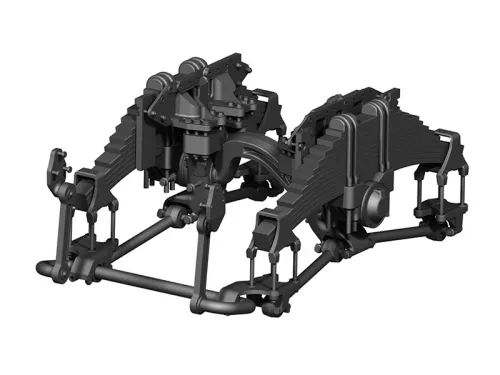

Dual reduction drive axle technology licensed from Daimler-Benz

Dual reduction drive axle technology licensed from Daimler-Benz

- Beiben was the first in China to adopt Daimler-Benz’s dual reduction drive axle technology.

- The axle housing is made from ductile cast iron and manufactured as a single integrated casting for enhanced strength and durability.

- According to tests conducted by nationally accredited institutions, the axle housing can withstand 2.5 times the rated load for over 1.17 million fatigue cycles without cracking.

Integrated balance suspension system based on Daimler-Benz design

Integrated balance suspension system based on Daimler-Benz design

- Equipped with an integrated balance suspension system developed using Daimler-Benz technology.

- The suspension adopts a combination of leaf springs, balance suspension, thrust rods, and stabilizer bars to ensure stability under load.

- Delivers high load-bearing capacity and excellent long-term reliability.

Powered by Weichai high-performance engines

Powered by Weichai high-performance engines

- All vehicle models are equipped with Weichai engines, known for their strong reliability and high-performance output.

- The engines are built with a high degree of structural reinforcement and generous design margins. Durability is proven through over 15,000 hours of bench testing and more than 50 million kilometers of road testing.

- Engine lifespan exceeds 1.8 million kilometers or 30,000 hours, supporting long-term, high-intensity usage.

- Strong environmental adaptability: maintains full power output at altitudes up to 2,800 meters, with minimal power loss under regular operation at 4,500 meters.

- Ensures flawless cold-start performance, with zero-startup failures at -20°C.

Equipped with FAST brand gearbox

Equipped with FAST brand gearbox

All vehicle models are equipped with FAST brand gearbox, delivering proven performance across a wide range of applications.

- Features a dual-countershaft design that enables power splitting and compact axial dimensions while maintaining high torque output.

- Reinforced key gear positions ensure reliable operation under complex and demanding working conditions.

- Offers a wide range of gear ratios for optimized powertrain matching based on application needs.

- Achieves a B10 service life of up to 1.2 million kilometers, placing it among the most reliable transmission systems in the global heavy-duty truck industry.