The main truck assembly facility is divided into four core operational zones, each serving a distinct function in the vehicle production process. The production zone includes a complete chassis assembly workshop, supported by line-side component warehouses and a centralized oil supply station. The main assembly line comprises 49 dedicated workstations, while six pre-assembly sub-lines ensure efficient preparation of key parts and modules. Adjacent to this area is the inspection and testing zone, where all vehicles undergo rigorous evaluation. This includes multi-stage diagnostics such as 3C system checks and comprehensive quality assessments carried out in dedicated workshops.

To simulate real-world driving conditions, the trial run zone features various surface types, including acceleration and braking strips, washboard and pothole roads, twisted terrain, and cobbled tracks. This ensures each truck performs reliably under demanding scenarios before it leaves the plant. Finished vehicles are stored in a 13,000 m² dispatch and holding area, which also serves as the central hub for vehicle delivery and logistics coordination.

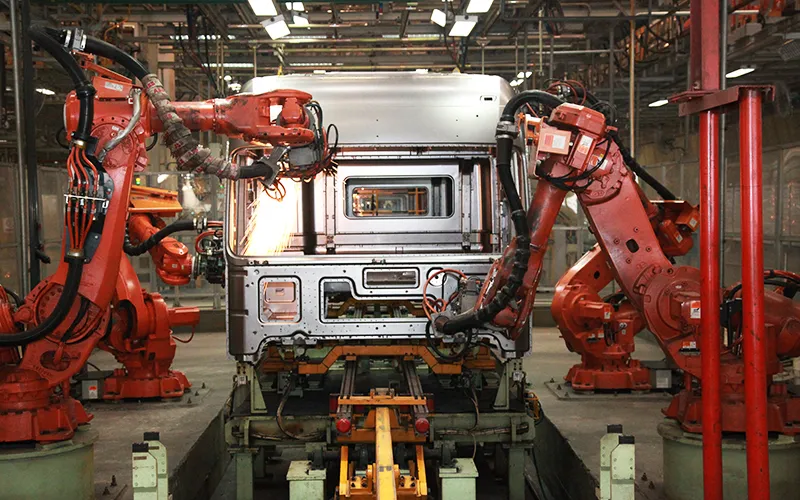

The cab production line is housed within a purpose-built facility with an annual capacity of 60,000 units. This plant manufactures cabs for the NG80 and V3 series, and its U-shaped layout connects four main production workshops: stamping, welding, coating, and assembly, via enclosed vestibules. The integrated design supports a seamless transition from raw materials to fully assembled cab modules, all under stringent quality control protocols.

Beiben also operates a dedicated axle production facility built on the complete technological system of Germany’s Daimler-Benz. This plant specializes in the manufacturing of heavy-duty axles, equalizing suspension systems, and essential chassis components. Over 70% of the equipment used on-site is imported, including advanced machining systems, precision assembly lines, high-efficiency painting systems, and state-of-the-art inspection tools. Core components such as axle housings, final drive housings, and differential housings are produced in-house to ensure optimal performance and long-term durability.

Through this integrated manufacturing infrastructure, Beiben delivers consistent quality and customizability across its heavy-duty vehicle lineup, meeting the demands of global transport, mining, construction, and energy industries.