NG80 Trucks

4×2 Truck Tractor

The 4×2 truck tractor is equipped with a 380 HP or 420 HP inline six-cylinder engine, paired with a 12-speed manual transmission and dual reduction rear axle. The 4×2 units have two driven wheels on a single axle, resulting in a 15% reduction in initial procurement costs and a 10% decrease in operating expenses compared to 6x4 model, making it a more economical choice for long-haul operations on paved roads. It offers reduced weight and improved fuel economy, making them well-suited for transporting lighter cargo and handling regional or short-haul deliveries.

-

Engine power 380 HP / 2200 rpm,

420 HP / 2100 rpm -

Gross combination weight 43,000 kg

-

Fuel tank capacity 400 liters

-

Emissions rating Euro II

| Model | ||

| Driving Type | 4×2 | 4×2 |

| Cab | Cab Exterior Metal bumper Three-step ladder Exterior sun visor Sun roof (manual) Rear view mirror (manual adjustment) Cab Interior Air-sprung suspension driver's seat Cooling and heating air conditioner Steering wheel (with adjustable height and angle) Door lock (manual) Radio (with MP3 player) Digital instruments | |

| Engine | Type:WP10.380E32 Version:EURO II Displacement (I):9,726 Max. Power (HP/rpm):380/2200 Max. Torque (N.m/rpm):1460/1400~1600 Cylinder:6 in-line | Type:WP12.420E32 Version:EURO II Displacement (I):11,596 Max. Power (HP/rpm):420/2100 Max. Torque (N.m/rpm):1750/1200~1500 Cylinder:6 in-line |

| Transmission | 12JS160T / 15.53-1 Gears:12 speed forward/2 speed reverse Synchromesh or Constant Mesh:Synchromesh Transfer Box:not available Power Take-Off (P.T.O.):optional | 12JS200T / 15.53-1 Gears:12 speed forward/2 speed reverse Synchromesh or Constant Mesh:Synchromesh Transfer Box:not available Power Take-Off (P.T.O.):optional |

| Steering System | 8098 Recirculating ball steering gear,hydraulic booster | |

| Clutch | Ø430mm single dry friction disc,diaphragm spring,pushing type | |

| Fuel Tank | 400L (iron) | |

| Front Axle | 7500kg,non-drive steering | |

| Rear Axle | 13000kg,double reduction driving axle,hydraulic shock absorber,differential lock | |

| Suspension | Front 13pcs / Rear 9+8pcs hard parabolic spring | |

| Brakes | Service:dual circuit air brakes Emergency/Parking:spring potential brake Auxiliary:EVB (optional ABS) | |

| Electrical Equipment | Alternator:70Amp Starter Motor:5.5kW Batteries:2×12V – 135AH | |

| Performance Data | Gradeability@GVM:30% Max. Geared Road Speed:80km/h Final Drive Ratio:5.263 (optional 4.769,5.921) | |

| Tyre | Size and Ply Rating:12.00R20-18PR Steel Rim | |

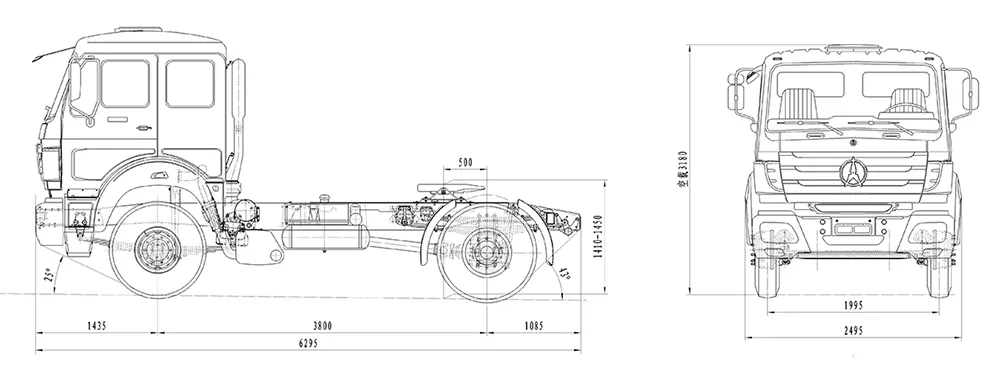

| Dimensions | Wheel Base (WB):3800mm Overall Length (OL):6320mm Overall Width (OW):2495mm Overall Height (OH):3180mm Front Overhang (FOH):1435mm Rear Overhang (ROH):1085mm Front fitting radius of semi-trailer:2300mm Rear fitting radius of semi-trailer:1850mm | |

| Total Vehicle Weight | 7900kg | |

*The above data is subject to the actual product.

Complete cab system developed using Daimler-Benz technology

- Developed using the complete cab technology introduced from Daimler-Benz.

- The NG80 cab features a semi-floating suspension system with high structural rigidity and energy absorption, providing enhanced driver protection.

- Manufactured with high-strength steel panels through integrated stamping, combined with a multi-cavity structural design for increased rigidity.

- Successfully passes pendulum impact testing and complies with EU crash safety certification standards. Ideal for engineering applications and mixed operating conditions

Daimler-Benz frame technology with proven load-bearing performance

Developed using Daimler-Benz technology, the frame features a variable-section, fish-belly-shaped composite beam design. The inner and outer frame rails are formed through a single-pass stamping process, delivering outstanding load-bearing performance. The result is a frame system renowned for its exceptional durability and structural strength, widely trusted in demanding heavy-load applications.

Dual reduction drive axle technology licensed from Daimler-Benz

- Beiben was the first in China to adopt Daimler-Benz’s dual reduction drive axle technology.

- The axle housing is made from ductile cast iron and manufactured as a single integrated casting for enhanced strength and durability.

- According to tests conducted by nationally accredited institutions, the axle housing can withstand 2.5 times the rated load for over 1.17 million fatigue cycles without cracking.

Dual-spring (main and auxiliary) suspension system based on Daimler-Benz technology

- Features a balance suspension system with a well-engineered combination of leaf springs, shock absorbers, and stabilizer bars

- Developed with Daimler-Benz technology, the design of the suspension system is among the most advanced and well-established in China

- Delivers outstanding load-bearing strength and dependable performance under demanding conditions

Powered by Weichai high-performance engines

- All vehicle models are equipped with Weichai engines, known for their strong reliability and high-performance output.

- The engines are built with a high degree of structural reinforcement and generous design margins. Durability is proven through over 15,000 hours of bench testing and more than 50 million kilometers of road testing.

- Engine lifespan exceeds 1.8 million kilometers or 30,000 hours, supporting long-term, high-intensity usage.

- Strong environmental adaptability: maintains full power output at altitudes up to 2,800 meters, with minimal power loss under regular operation at 4,500 meters.

- Ensures flawless cold-start performance, with zero-startup failures at -20°C.

Equipped with FAST brand gearbox

All vehicle models are equipped with FAST brand gearbox, delivering proven performance across a wide range of applications.

- Features a dual-countershaft design that enables power splitting and compact axial dimensions while maintaining high torque output.

- Reinforced key gear positions ensure reliable operation under complex and demanding working conditions.

- Offers a wide range of gear ratios for optimized powertrain matching based on application needs.

- Achieves a B10 service life of up to 1.2 million kilometers, placing it among the most reliable transmission systems in the global heavy-duty truck industry.

- Fuel tank: Optional fuel tank capacities are available based on customer requirements.

- Tire specifications: Available tire size options include 315/80R22.5, 14.00R20, 12R22.5, 12.00R24

- Urban and short-haul intercity delivery: Ideal for loads up to 30 tons, the 4×2 tractor unit offers up to 15% lower fuel consumption per 100 km compared to 6×4 models. With a turning radius of ≤7 meters, it is well-suited for express logistics and cold chain distribution within congested urban areas and regional highways within 200 km.

- Port container transfers: Compatible with 20-foot and 40-foot containers, this model is optimized for port and industrial zone shuttle operations on flat surfaces. Compared to multi-axle trucks, it can cut transfer costs by up to 25% and extend maintenance intervals by 30%, making it a cost-effective choice for short-range container movement.

- Light bulk cargo transport: Supports loads up to 15 tons and is suitable for short-range highway transportation within 200 km, especially for lightweight or high-volume goods.